The historical Aztec and Mayan civilisations had been maybe the primary to start making paper out of sisal leaves. Since then, the stiff, inexperienced sword-like leaves have been used to make twine, material, and carpets. The plant itself can be used to make mezcal, a distilled alcoholic beverage.

Now, in a transfer to make menstrual hygiene merchandise more environmentally sustainable, scientists at Stanford University have reported a way to supply from sisal leaves a “highly absorbent and retentive material”.

As a end result, the researchers posit in their Nature Communications Engineering paper, the fabric can probably substitute cotton, wooden pulp, and chemical absorbents in sanitary napkins.

The absorption capability of the fabric is larger than these discovered in business menstrual pads, they add.

The research’s authors additionally declare that their technique makes use of no polluting or poisonous chemical compounds, could be carried out regionally at a small scale, and is environmentally sustainable.

Led by affiliate professor of bioengineering Manu Prakash, the group is at the moment working with a Nepal-based non-governmental organisation to check whether or not their technique could be scaled as much as mass produce sanitary napkins and meet the rising demand for low-cost and ‘green’ menstrual hygiene merchandise.

Access to hygienic menstruation

In 2022, the Centre for Economic Data and Analysis at Ashoka University reported that there was a big rise in the variety of folks utilizing hygienic strategies – i.e. sanitary napkins, tampons, and menstrual cups – to handle their menstruation in India.

Despite this promising progress, entry to menstrual hygiene merchandise stays restricted for round 500 million folks worldwide. In rural India, for instance, solely 42% of adolescent ladies use solely hygienic strategies to handle their durations.

One key barrier in making menstrual hygiene merchandise, like sanitary napkins, accessible is the rising price of uncooked supplies and distribution.

The absorbent materials in sanitary napkins is usually a mixture of wooden pulp and artificial superabsorbent polymers (SAPs). The latter are supplies that may soak up a considerable amount of fluid relative to their very own mass.

Even as State and Central governments in India are working to make sanitary napkins obtainable extensively at decrease costs, consultants say that their widespread use is environmentally unsustainable.

According to gynaecologist Shehla Jamal, founder and president of the Society for Menstrual Disorders and Hygiene Management, “Menstrual sanitation waste is adding non-biodegradable waste in the environment [in bulk],” and in flip, constituting an environmental hazard.

For instance, based on estimates from a 2022 United Nations Population Fund report, Patna alone discards 9.8 billion sanitary napkins yearly. Another estimate from a 2022 research positioned the month-to-month amount of discarded sanitary napkins in Chennai at 27 million a month.

Dr. Jamal additionally stated that single-use sanitary napkins comprise dioxin, which is a persistent environmental pollutant in addition to a carcinogen that places customers of sanitary napkins vulnerable to most cancers. The International Agency for Research on Cancer (IARC) classifies dioxin as a “known human carcinogen”.

A sturdy succulent

Owing to the rising environmental considerations round menstrual sanitation waste, scientists have in the previous contemplated over methods to make sanitary napkins more environmentally sustainable. Chandra Shekhar Sharma, a professor of chemical engineering on the Indian Institute of Technology, Hyderabad, instructed this reporter that different plant fibres – like these obtained from banana vegetation – have been used to synthesise absorbent materials for sanitary napkins.

Prof. Sharma’s group in the previous has additionally tried to cut back using SAPs in sanitary napkins by changing them with cellulose-based nanofibers.

However, there’s one downside with relying solely on banana vegetation for plant-based absorbent supplies. Access to hygienic menstruation is most restricted in low- and middle-income international locations, a lot of that are positioned in the tropics and are susceptible to drought. Banana vegetation are notably delicate to drought and due to this fact not sustainable decisions with which to supply sanitary napkins in areas which can be arid or semi-arid and drought-prone.

From the paper: e) Illustration displaying sisal leaf and cross part. f) Photograph of dried macrofibres obtained from leaf through decortication. g) Schematic of decorticated macrofibres in (f) displaying its hierarchical construction. h) Photograph displaying fluff pulp obtained from decorticated macrofibres through gentle delignification with peroxyformic acid and mechanical therapy. i) Illustration of fibres proven in (h).

| Photo Credit:

https://doi.org/10.1038/s44172-023-00130-y

Enter sisal. Like all succulents, that are vegetation with thickened components to retailer more water, sisal has an uncanny means to retailer water and thrive in drought-prone areas. Its leaves develop as much as 2 m lengthy. The lifespan of a sisal plant is about 7-10 years, throughout which it produces 200-250 usable leaves. Each leaf has a couple of thousand fibres that can be utilized to make ropes, paper, and material. Now, it may very well be used to make a extremely absorbed materials as properly.

Dr. Prakash first heard of sisal from his pal Alex Odundo, a Kenyan engineer. Mr. Odundo, additionally a co-author of the paper, has been serving to sisal farmers in Kenya develop the crop more effectively.

“Before sisal, we tested whatever fibrous plant we could lay our hands on,” Dr. Prakash stated. Being based mostly in California, the group started with bamboo. The journey to search out sustainable absorbent materials then took them to Nigeria, Kenya, Nepal, and India, the place they examined fibres from banana, rice, and water hyacinth as properly.

But based on their exams, “nothing beats sisal,” Dr. Prakash stated.

Inspired by termite guts

The course of that Dr. Prakash’s group has developed begins by feeding sisal leaves right into a machine. This machine is a decorticator: it mechanically separates the fibres. In the following step, known as delignification, a polymer known as lignin, discovered in plant cell partitions that repels water, is dissolved away. What stays is very absorbent cellulose fibre.

Traditionally, the delignification course of for changing wooden to absorbent wooden pulp includes treating wooden chips with a harsh chemical combination containing water, sodium hydroxide (a robust alkali), and sodium sulphide. This course of, known as the Kraft course of, is efficient but additionally produces risky and poisonous by-products that may trigger each air and water air pollution.

For a more environmentally sustainable strategy to delignify sisal leaves, Dr. Prakash and his group turned to the setting – the place they discovered two organisms notably adept at changing wooden to wooden pulp: termites and wood-rot fungi.

“Termite guts have an incredible consortium of organisms,” stated Dr. Prakash. This consortium, comprising microbes of many sizes and shapes, delignifies wooden in a course of that scientists don’t utterly perceive.

They do know, nevertheless, that one essential compound in this course of is peroxyformic acid.

Treatment with peroxyformic acid “selectively removes lignin while preserving the structure of the cellulose microfibers”, the authors write in their paper. The compound can be reused over a number of cycles and it decomposes into water and carbon dioxide on the finish of the method. This decomposition requires no neutralising chemical compounds, which minimises environmental injury.

“The amount of CO2 released in breakdown of peroxyformic acid is minuscule compared to the total CO2 in the overall analysis (say, compared to transportation related CO2) or total carbon even in the materials being used itself,” Prof. Prakash stated.

Sisal’s fluff pulp

After treating the sisal fibres with peroxyformic acid, the method proceeds by washing them first with an answer of dilute sodium hydroxide after which water. The result’s a moist pulp that’s then dried and mechanically blended to acquire a dry mass known as a fluff pulp.

When the researchers in contrast the absorption capability of this fluff pulp to cotton obtained from commercially manufactured sanitary napkins, or Cotton-CMP, they discovered that the fluff had the higher hand in normal absorption exams.

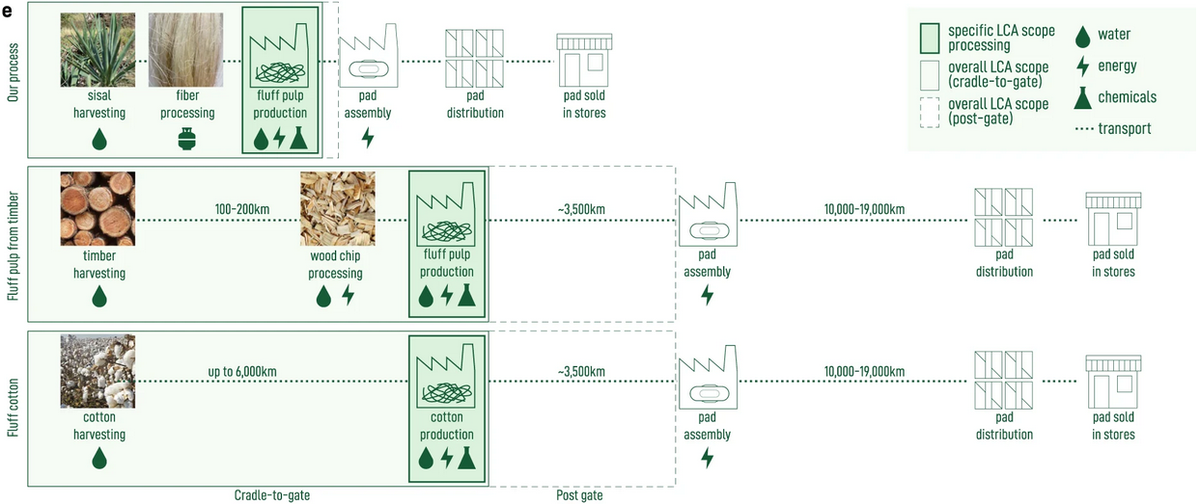

From the paper: Schematic displaying actions described in the life-cycle evaluation, with bins defining the actions inside every scope of the evaluation.

| Photo Credit:

https://doi.org/10.1038/s44172-023-00130-y

The researchers additionally carried out a “cradle-to-gate” carbon footprint evaluation by estimating the environmental footprint of a product from the extraction of uncooked supplies to the time when it leaves the manufacturing unit gate.

In what they name an “aspirational case” – when the uncooked supplies, together with these required to supply the peroxyformic acid, could be produced on-site utilizing photo voltaic vitality – the environmental footprint of their course of was “comparable” to that of economic processes that extracted fibre from timber and cotton. The water consumption was additionally discovered to be similar to that of economic processes to supply absorbent supplies from timber, cotton, and papyrus.

Given the cultivation of sisal requires much less water and is much less environmentally damaging than cotton industries, Dr. Prakash believes changing cotton-CMP with sisal fluff pulp may make sanitary serviette manufacturing more environmentally sustainable in the long term.

According to him, there’s a “25-fold difference” in water use “for cultivation and harvesting” “between cotton and sisal”.

He additionally acknowledged timber may very well be an alternative choice to cotton, however solely in components of the world which have an “endless supply of sustainably harvested forests”.

“That’s not an option for places like India or Africa.”

Roping in high-school college students

Dr. Prakash is happy for the outcomes of their pilot “at-scale” manufacturing in Nepal, the place he stated he and his group produce other grand plans as properly. For instance, the power in Nepal gained’t solely be a producing unit but additionally a educating and coaching web site. “We will use this pilot site to teach anybody and everybody interested in replicating this process at scale,” he stated.

The group can be beginning a worldwide programme to have interaction college students world wide in testing the usability of different vegetation utilizing the method reported in their paper. According to Dr. Prakash, they “have reported a very general process. Using this process, anybody can test any number of plants.”

In this programme, highschool college students might be inspired to check native vegetation by means of this course of and report their findings in a public database, based on him. Increasing the variety of vegetation is essential given completely different geographical areas of the world have completely different environmental situations, and completely different vegetation that thrive there.

In their paper, the group reported that it has already utilized its course of to supply fluff pulp from flax and hemp.

Local manufacturing, native management

Dr. Jamal, the gynaecologist, lauded the research but additionally stated that sturdy analysis is required to make sure plant fibre-based menstrual hygiene merchandise reside as much as current high quality requirements. According to Prof. Sharma at IIT Hyderabad, “the on-field performance of such plant based fibre products is [often] not at par with existing products”.

To allay considerations round high quality, Dr. Prakash’s group is partnering with organisations in Nigeria, Kenya, and Nepal to implement “distributed quality control” of the absorbent materials.

The course of that the authors describe in the paper can be geared in direction of “distributed manufacturing” of environmentally sustainable sanitary napkins.

Here, as an alternative of counting on large-scale centralised manufacturing, producers work at smaller scales and cater to native populations. Distributed manufacturing additionally eliminates carbon emissions resulting from long-distance transportation.

Dr Prakash’s supposed partnership, if profitable, would additionally distribute high quality management of the sanitary napkins thus produced amongst more native amenities.

He sees this work as a “research arm” for the motion addressing interval poverty and menstrual well being, he stated. His group is at the moment constructing a analysis consortium the place different scientists in addressing the shortage of entry to menstrual merchandise can contribute in an “open source framework”.

Dr Prakash additionally stated they “wish to collaborate with entrepreneurs globally on the ground who are trying to solve the problem from the bottom up, but don’t have the kind of research and scientific resources needed to build high quality products.”

Sayantan Datta is an impartial science journalist. They are at the moment a college member at Krea University and tweet at @queersprings.